When Do I Need a Professional Soda Blaster?

Soda blasting is the process of propelling a mixture of baking soda and compressed air through a blast hose at a desired surface. One of the early uses of large-scale soda blasting was in the 1980s when New York City engineers were trying to figure out how best to restore the exterior surface of the Statue of Liberty. Aiming to minimize the environmental impact of the project and not wanting to damage the statue’s soft copper plating, the engineers decided to use sodium bicarbonate (also known as baking soda) as the blasting media.

When baking soda particles make contact with a contaminate, they explode, disrupting the contaminate, yet leaving the underlying surface unharmed. Because of this unique feature, soda blasting can be safely used on such materials as aluminum, brick, concrete, steel, stucco, tile, and wood, among many others. Since the 1980s, soda blasting has grown in popularity and is now used in projects ranging in size from small household cleanings to large industrial restorations.

So, how do you know if soda blasting is right for a restoration project at your home or for your business? Below is a list of projects that are perfect for soda blasting:

– Fire Restoration: Soda blasting not only removes smoke and soot damage from various structures, but it also acts as a natural deodorizer, absorbing and eliminating the lingering smell caused by the fire. We’ve restored dozens of fireplaces after soot had stained the surrounding bricks.

– Flooring Restoration: Soda blasting is an excellent option for removing build-up, spills, or stains from such indoor and outdoor flooring surfaces as concrete, wood, asphalt, and granite.

– Graffiti Removal: Soda blasting won’t damage underlying surfaces such as brick, sandstone, or marble, due to the relative softness of baking soda. Also, it’s more cost-friendly than many of the other expensive graffiti removal options.

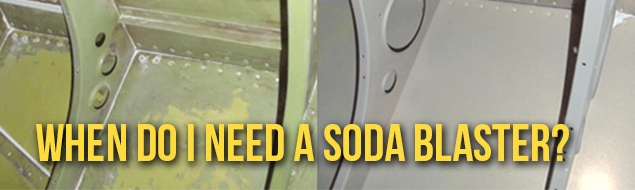

– Specialty Projects: We’ve used soda on a number of unique projects with various surfaces. For example, we restored an old Grumman Goose Airplane using just the right level of pressure and abrasiveness as to not hurt the integrity of the plane’s structure.

These are just some of the few restoration projects that are perfect for the remarkably effective and environmentally friendly option of soda blasting. Often, we’ll use a specific combination of materials—sometimes sand, dry ice, and other blasting medias, when combined with soda blasting, produce the best results.

In some cases, soda may not be the best solution. Even the Statue of Liberty, for instance, had grey streaks running down her face (which faded out over time) as a result of the soda/copper reaction. The soda did not damage the patina but it did have a funky temporary reaction. Hiring us means we know when chemical reactions will occur and have other recommendations for your project when we think (or know) that it could go wrong.

Another issue is using it on wood and then having the area exposed to “the elements”. It can turn the wood green, which is why we would use another media—walnut or corncob—to do these types of projects.

We here at Crystal Soda Blast encourage you to learn more by visiting the soda blasting page on our website.

Related Articles: