DRY ICE BLASTING

Dry ice blasting is a relatively new cleaning process. It is similar in principle to sand blasting, but instead uses compressed air to accelerate solid carbon dioxide (CO²) dry ice pellets to literally strip surfaces of a multitude of residues, including: mold and dirt, ink and paint, glue, food and grease, oil, rubber mold release agent, and numerous other contaminants.

A compressed air supply of up to 150 PSI/210scfm can be used in this process.

Once a project has been scheduled with us, dry ice pellets need to be ordered 48 hours in advance and can be delivered to the job site or stored at Crystal Soda Blast headquarters until needed depending on job site space. Pellets are made from food grade carbon dioxide that has been specifically approved by the FDA, the EPA and the USDA. Carbon dioxide is a non-poisonous, liquefied gas, which is both inexpensive and easily stored at work sites.

Dry Ice "Rice" is stored and transported typically in coolers. Different size coolers are available depending on the size of the project and the amount of ice required. We typically order 500lbs in rolling coolers for ease of use. Typical mold remediation uses between 3 to 7 lbs of "rice" per minute when running the Dry Ice Blaster.

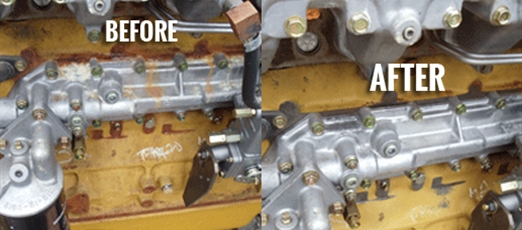

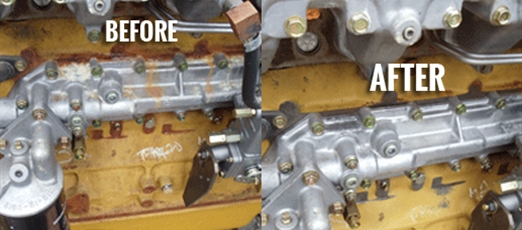

Unlike sandblasting, dry ice blasting is non-abrasive, which means it the ideal choice when no surface roughness is desired. This is due to the relative softness of a solid CO², which is not as dense and hard, as other projectile media. When dry ice pellets hit a surface, such as a metal part contaminated with oil and grime, the dry ice pellets immediately sublimate (change in form from solid to gas). Pellets are propelled against a substrate at high speed and convert from a solid to a vapor leaving no residue, unlike sandblasting. It also doesn't leave toxic waste as solvents can. It lets you skip clean-up problems associated with other cleaning methods.

The elimination of additional secondary waste is why many industries are choosing dry ice blasting as an alternative to sandblasting, glass bead blasting, hydro-blasting, solvents, and other cleaning methods. Dry ice cleaning is also environmentally responsible.

Since dry ice is in fact "dry", dry ice blasting is also the preferred choice when cleaning machinery, electrical components, and sensitive equipment in enclosed facilities or confined spaces. It is capable of getting into tight spaces and crevices that other methods cannot. You can also take the dry ice blasting system to your equipment - cleaning it in place without risky and time-consuming material handling. It is nonabrasive, nonconductive, and nonflammable and generally results in a much faster cleaning process, in many cases up to 75% faster. Dry ice blasting is great for mold remediation projects and comes highly approved by industrial hygienists.

In addition to being clean and safe, it is also important to remember that dry ice is obtained as a byproduct of other industrial processes; i.e., it is made from reclaimed CO². It does not produce CO² or add CO² to the atmosphere and therefore does not contribute to the greenhouse effect.

Dry ice blasting is truly, and completely, environmentally friendly!

Our staff is ready to collaborate with your team, learn your planned maintenance needs, schedule and complete the work. We are equally ready to respond to your industrial cleaning emergencies no matter what time or day they happen.

Types of surfaces

Steel / Mold / Wood / Stone / Iron

Do you have a Small Project That Needs Blasting?

If you have a movable item to blast such as a car or small boat, we recommend taking it to one of the local blast booths.